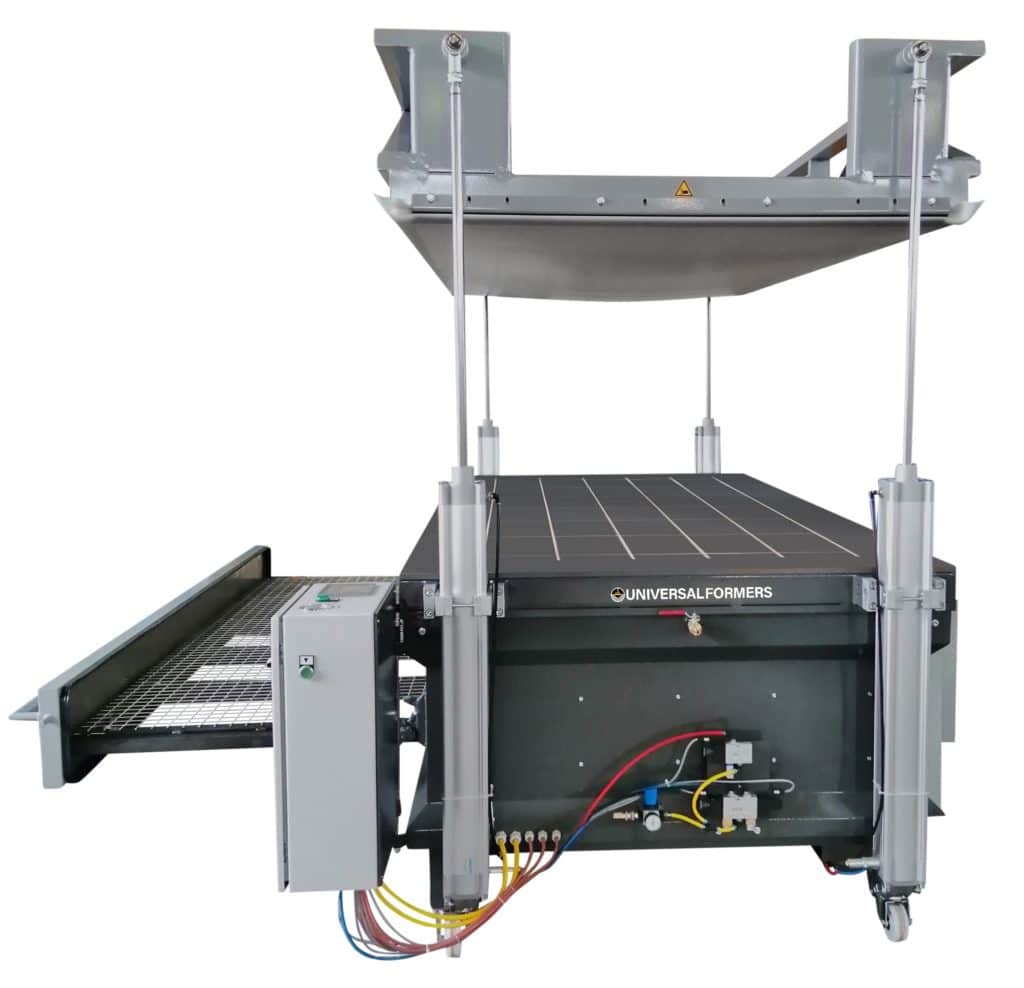

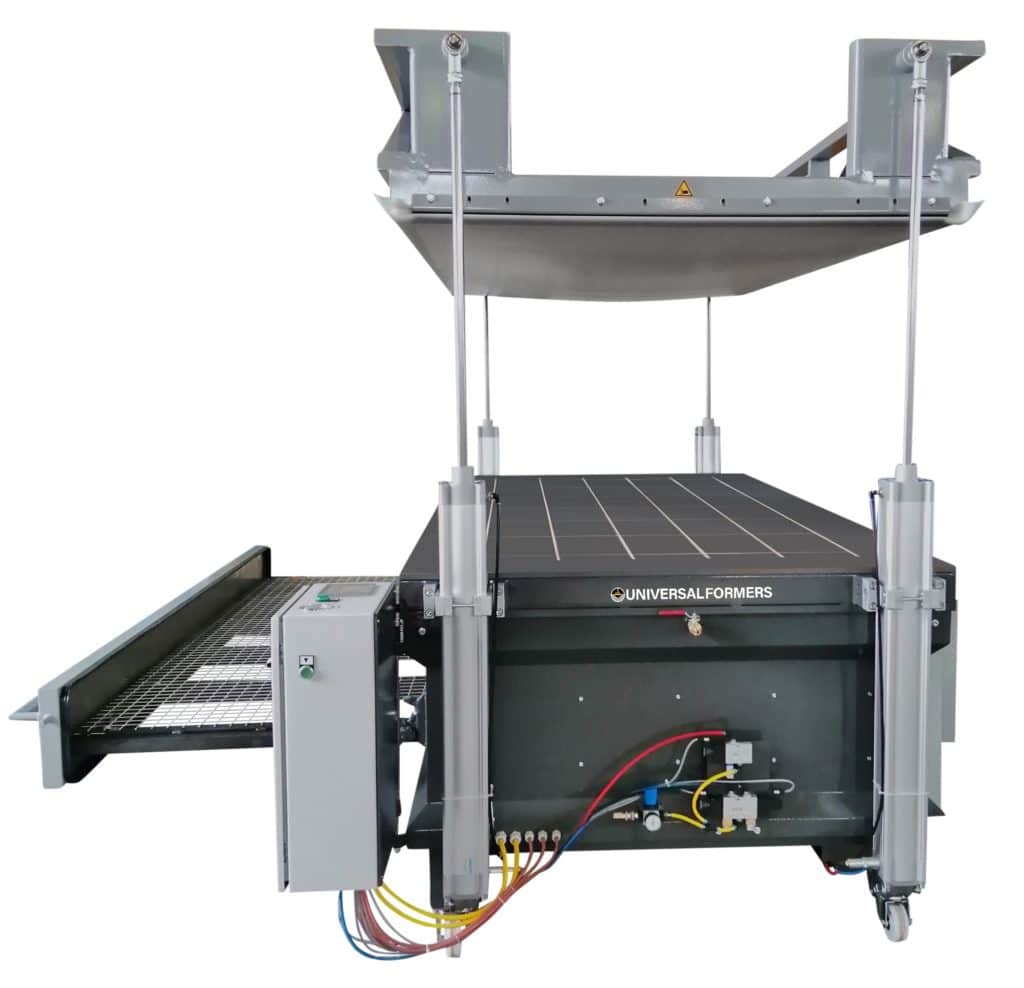

DUOFORMER - Die Vakuumpresse mit Heizung

DUOFORMER FÜR MINERALWERKSTOFFE

Die kombinierte Vakuumpresse mit Heizung ist sehr kompakt und platzsparend. Diese Zwei-in-Eins-Verbindung ermöglicht es, thermoformbare Werkstoffe in unterschiedlichen Stärken und Qualitäten mit der ausgeklügelten *CAS-Umluftheizung rasch und absolut gleichmäßig aufzuheizen. Anschließend wird der erwärmte Werkstoff mit Vakuumdruck über eine Form in das gewünschte Werkstück umgeformt.

*CAS=Controlled Air Stream

DUOFORMER VORTEILE

Formen und Pressen mit der bewährten Klappenöffnung, oder der leistungsstarken Vertikalbewegung.

Aufheizen und Umformen von Mineralwerkstoffen wie:

CORIAN, HIMACS, KERROCK, HANEX, STARON, MISTRAL, AVONITE, TRISTONE, VELSTONE, WILSONART, GETACORE, RAUVISIO, VARICOR, PLEXICOR, MEGANITE, KRION, LIVINGSTONE, MARLAN, EOS, FORMICA, MYSTERA, etc.

Aufheizen und Umformen aller anderen thermoplastischen Werkstoffe wie:

ABS, PMMA (Plexiglas, Perspex, Lucite), PET-G (Vivak), PE, PS, PP, PVC-U, PC (Makrolon), UPM-GRADA, RESYSTA, NFPP, etc.

Vakuumpresse

zum Bekleben, Beschichten, Flachpressen, Formverleimen, Furnieren, Kanten und Profile anbringen, Umformen, Verkleben, Verleimen, Verpressen

Vollverschweißte Ganzstahlkonstruktion im Zweikammersystem. Die dickwandigen Stahlprofile nehmen die Spannungen auf, wenn die Maschine aufgeheizt wird.

Weitere Vorteile:

Thermische Trennung mit zusätzlicher Isolierung zwischen Heizstation und Vakuumtisch, die Heizenergie bleibt in der Heizkammer.

Leistungsstarkes und effizientes CAS-Heizsystem (Controlled Air Stream) für die gleichmäßige Aufheizung aller Materialien!

Vakuumpresse mit Heizung in Temperaturbereichen bis +230 °C!

Als Zusatzfunktion: die einfach aushängbare Heizlade zum Tempern von Kunststoffen und Aufheizen von großvolumigen Werkstücken

Hitzegeschützte Bedienungselemente in einem separat schwenkbaren Schaltschrank.

Innovative und solide Vakuumpresse, siehe Vacuformer

Membran-Schnellwechselsystem für alle Membranen (Naturkautschuk, Silikon, Polyolefinfolien, Hochtemperaturfolien) in jeder Stärke

Einfacher Arbeitsablauf – schnell vom Werkstoff zum Werkstück!

Energiesparend und sehr wirtschaftlich.

Mobile Arbeitsstation – kann überall in der Werkstatt eingesetzt werden.

Wertbeständige und robuste Maschine – Made in Austria for life!

Duoformer-Übersicht

voll geschweißte, verwindungssteife, robuste Stahlkonstruktion

einfaches Öffnen und Schließen

Wechsel unterschiedlicher Membranen in kurzer Zeit

mit Absaugkanälen für einen schnellen Vakkuumaufbau

Temperatur bis + 230°C, ausziehbar und einfach auszuhängen!

schwenkbar an der Seite

hitzebeständige, sehr dehnfähige, transparente Silikonmembrane

Mehr Informationen finden sie in den Datenblättern

Hier gehts zu den Downloads

Zusätzliche, präzise Pressleistung bei hohen komplizierten Teilen!

Duoformer - Klappe

Die mehrwertbringende Aufheiz- und Pressmaschine!

DUOFORMER

Für die Zukunftssicherung Ihres Unternehmens!

Universalformers Eine Marke der Lechenauer GmbH www.lechenauer.at